Unlocking Unprecedented Clarity: The Quantum Leap in Optical Coatings

In the world of materials science, few innovations hold as much transformative potential as quantum dots (QDs). These minuscule semiconductor nanocrystals are at the forefront of a technological revolution, particularly in the realm of optical coatings and light management. For researchers and industries across India, from burgeoning solar energy farms in Gujarat to the high-tech display manufacturing hubs in Tamil Nadu, understanding the impact of QDs is no longer optional—it's essential for staying competitive.

At its core, the challenge with any optical surface—be it a camera lens, a skyscraper window, or a photovoltaic cell—is reflection. Unwanted reflection reduces the efficiency of light transmission, leading to energy loss, glare, and diminished performance. For decades, the solution has been anti-reflective coatings, typically made of multiple layers of thin films. While effective, these traditional methods are approaching their physical limits. This is where nanomaterials, specifically quantum dots, enter the picture, offering a paradigm shift in how we control light.

The development of advanced quantum dots for anti-reflective coating applications is not just an incremental improvement; it's a fundamental change. Instead of just passively reducing reflection through destructive interference, QD-infused coatings can actively manage photons. This opens up possibilities for coatings that not only transmit more light but also convert its properties to better suit the application. This article delves into the science, benefits, and burgeoning opportunities of using quantum dots to pioneer the next generation of coating technology, with a special focus on its relevance to the Indian R&D landscape.

Why Indian Researchers Should Focus on Quantum Dot Anti-Reflective Coatings

For the vibrant scientific community in India, exploring quantum dots in surface modification and thin films presents a wealth of opportunities. Here are the key benefits:

- Superior Performance: Quantum dot-based coatings can achieve near-zero reflection across a broad spectrum of light, surpassing the capabilities of conventional multi-layer coatings. This leads to unprecedented efficiency gains in optoelectronics.

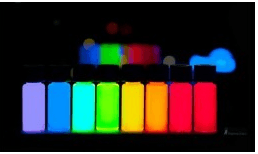

- Tunable Optical Properties: The primary advantage of QDs is their size-tunable bandgap. Researchers can precisely control the size of the nanocrystals to absorb and emit specific wavelengths of light, creating coatings tailored for unique applications, from UV protection to enhanced night vision.

- Simplified Fabrication: While synthesizing QDs requires expertise, applying them as a coating can be simpler and more cost-effective than the vacuum deposition methods used for traditional thin films. Solution-based processes like spin-coating or spray-coating are well-suited for large-area applications.

- Multi-Functional Materials: Coatings incorporating quantum dots can be more than just anti-reflective. They can be engineered to be hydrophobic, self-cleaning, or even luminescent, adding significant value to the end product. This is a key area of nanomaterials research.

- Alignment with National Goals: With India's focus on renewable energy (National Solar Mission) and advanced manufacturing ('Make in India'), R&D in high-efficiency solar cells and advanced displays is a national priority. Expertise in QD-based light management directly contributes to these critical sectors.

Industry Applications: Where Quantum Dots Make a Difference

The impact of this technology spans multiple high-growth industries in India and globally.

Solar Energy

In solar panels, every photon counts. Anti-reflective coatings on the protective glass are crucial for maximizing the amount of light reaching the silicon cells. QD coatings can reduce reflection from ~4% to less than 1%. Furthermore, they can be designed as luminescent down-shifting layers, converting high-energy UV light (which solar cells use inefficiently) into visible light, directly boosting the panel's power output. This is a game-changer for achieving higher solar efficiency.

Displays and Lighting

From smartphones to 8K televisions, vibrant and bright displays are in high demand. Quantum dots are already used to create richer colors (QLED TVs). As an anti-reflective layer, they reduce ambient glare, improving visibility in bright conditions and enhancing contrast. This leads to a better user experience and can even lower the device's power consumption, as the backlight doesn't need to be as intense.

Lenses and Optics

For high-precision optics used in cameras, microscopes, and telescopes, internal reflections can create ghosting and flare, degrading image quality. Advanced optical coatings using quantum dots provide broadband reflection reduction, ensuring maximum clarity and signal integrity. This is critical for scientific imaging, defense applications, and professional photography.

Automotive and Aerospace

In automotive applications, QD anti-reflective coatings can be applied to windshields and dashboard displays to reduce glare for safer driving. In aerospace, they can protect sensitive sensors and windows from harsh radiation while ensuring maximum optical performance. The durability and multi-functional potential of these nanomaterials make them ideal for these demanding environments.

The Indian Landscape: Trends and Opportunities in Nanomaterials

The market for nanomaterials in India is on a steep upward trajectory. The government's Nano Mission program has been instrumental in building a robust R&D infrastructure across institutions like the IISc, IITs, and CSIR labs. This has created a fertile ground for deep-tech innovation in areas like coating technology and optoelectronics.

A key trend is the shift from cadmium-based quantum dots (like CdSe/ZnS) to more environmentally friendly alternatives such as perovskite, graphene, or InP-based quantum dots. Indian researchers are actively contributing to this global effort, aiming to develop low-toxicity, high-performance materials. The development of 'Cadmium-Free' quantum dots is not just an environmental choice but a strategic one, as it aligns with global regulations and opens up new markets, especially in consumer electronics and biomedical applications.

Furthermore, the synergy between India's IT prowess and materials science is creating unique opportunities in computational materials design. Scientists can now model and simulate the optical properties of different quantum dot structures before synthesizing them, dramatically accelerating the R&D cycle for new anti-reflective coatings. This data-driven approach to surface modification and thin film design is where India can establish a significant competitive advantage.

Frequently Asked Questions

Ready to Advance Your Research?

Connect with us to discuss your specific nanomaterial needs or to get a quote for high-purity quantum dots for your next project.

Contact Our Experts